An engine room ventilation system is a critical component of any marine vessel, designed to supply fresh air, remove heat, and ensure safe operating conditions for engines and auxiliary equipment. Whether on yachts, superyachts, or commercial vessels, effective ventilation directly impacts engine performance, fuel efficiency, fire safety, and crew comfort.

As modern vessels become more powerful and technologically advanced, properly engineered engine room ventilation systems have become essential for reliable and efficient marine operations.

What Is an Engine Room Ventilation System?

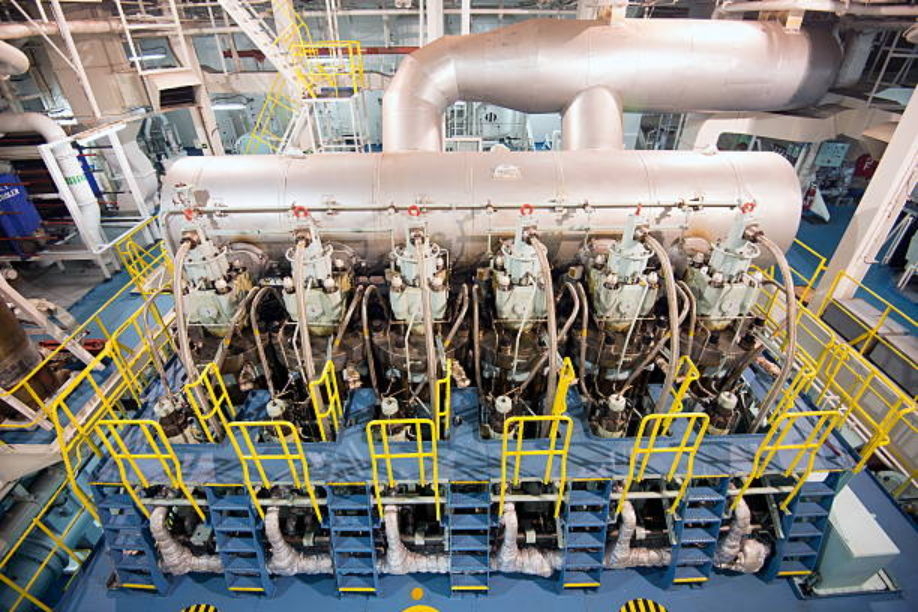

An engine room ventilation system is a mechanical and passive airflow system that controls the movement of air into and out of the engine room. Its primary purpose is to provide adequate combustion air, remove excess heat, dilute harmful gases, and maintain safe temperature levels.

The system typically consists of air intake ducts, exhaust ducts, fans or blowers, dampers, louvers, and sound attenuation components.

Importance of Engine Room Ventilation

Supplying Combustion Air

Marine engines require a continuous supply of clean, oxygen-rich air for efficient combustion. Insufficient airflow can lead to:

- Reduced engine power

- Increased fuel consumption

- Higher exhaust emissions

Proper ventilation ensures engines operate at optimal efficiency.

Heat Removal and Temperature Control

Engines, generators, and electrical equipment generate significant heat. Ventilation systems remove hot air and maintain safe ambient temperatures, preventing:

- Overheating

- Equipment failure

- Fire hazards

Safety and Gas Removal

Engine rooms may contain hazardous gases such as fuel vapors and exhaust fumes. Effective ventilation dilutes and removes these gases, improving safety for both equipment and personnel.

Key Components of an Engine Room Ventilation System

Air Intake Systems

Air intake systems draw fresh air into the engine room through ducts and louvers designed to prevent water ingress while maintaining airflow efficiency.

Exhaust Air Outlets

Exhaust outlets remove hot, contaminated air from the engine room, helping regulate temperature and air quality.

Ventilation Fans and Blowers

Mechanical fans or blowers provide forced airflow when natural ventilation is insufficient, particularly during high-load operation or in confined engine rooms.

Dampers and Fire Flaps

Fire dampers and shut-off flaps automatically close in the event of a fire, preventing the spread of flames and smoke through ventilation ducts.

Types of Engine Room Ventilation Systems

Natural Ventilation Systems

Natural ventilation relies on pressure differences and vessel movement to circulate air. While energy-efficient, it is often insufficient for larger or high-performance vessels.

Forced Ventilation Systems

Forced ventilation uses fans to actively control airflow, ensuring consistent air exchange regardless of vessel speed or weather conditions.

Hybrid Ventilation Systems

Hybrid systems combine natural and forced ventilation, offering flexibility and energy efficiency while maintaining optimal airflow.

Noise and Vibration Control

Acoustic Insulation

Ventilation systems are designed with acoustic liners, silencers, and insulated ducts to reduce noise transmission from the engine room to living spaces.

Vibration Isolation

Flexible connections and resilient mounts prevent fan and airflow vibrations from transferring to the vessel’s structure.

Materials and Construction

Marine-Grade Materials

Engine room ventilation systems are exposed to heat, humidity, and corrosive marine environments. Common materials include:

- Marine-grade aluminum

- Stainless steel

- Fire-retardant composite materials

These materials ensure durability and compliance with marine safety standards.

Regulatory and Safety Requirements

Engine room ventilation systems must comply with:

- International Maritime Organization (IMO) regulations

- Classification society rules (ABS, DNV, Lloyd’s Register, etc.)

- Fire safety and ventilation standards

Compliance ensures safe operation and certification approval.

Design and Integration Considerations

Customized System Design

Each vessel has unique airflow, space, and power requirements. Ventilation systems are custom-engineered to match:

- Engine size and quantity

- Engine room layout

- Heat load calculations

Space Optimization

Compact ducting and modular components allow efficient integration without compromising access for maintenance.

Maintenance and Operational Efficiency

Routine Inspection

Regular inspection of fans, filters, dampers, and ducting ensures consistent performance and prevents unexpected failures.

Energy Efficiency

Modern ventilation systems are designed to optimize airflow while minimizing power consumption, supporting fuel efficiency and sustainability goals.

Benefits of a Well-Designed Engine Room Ventilation System

- Improved engine performance

- Reduced fuel consumption

- Enhanced fire safety

- Lower noise levels

- Extended equipment lifespan

A reliable ventilation system contributes directly to the overall efficiency and safety of the vessel.

Conclusion

An engine room ventilation system is a fundamental element of marine engineering, ensuring that engines and auxiliary systems operate safely, efficiently, and reliably. By supplying fresh air, controlling heat, and removing hazardous gases, a properly designed ventilation system protects both the vessel and its occupants.

If you are planning a new build, refit, or system upgrade, contact us today to discuss custom engine room ventilation solutions. Our team of marine engineering specialists delivers high-performance, compliant, and efficient ventilation systems tailored to your vessel’s specific requirements.