In today’s fast-paced logistics and manufacturing industries, ensuring that products are securely packaged during storage and transport is essential. One of the most effective ways to protect goods is by using a black stretch film wrap. This versatile material offers strength, flexibility, and an added layer of privacy for your shipments. Choosing the right black stretch film wrap, however, requires careful consideration of several factors. This guide will walk you through everything you need to know to make an informed decision.

Understanding Black Stretch Film Wrap

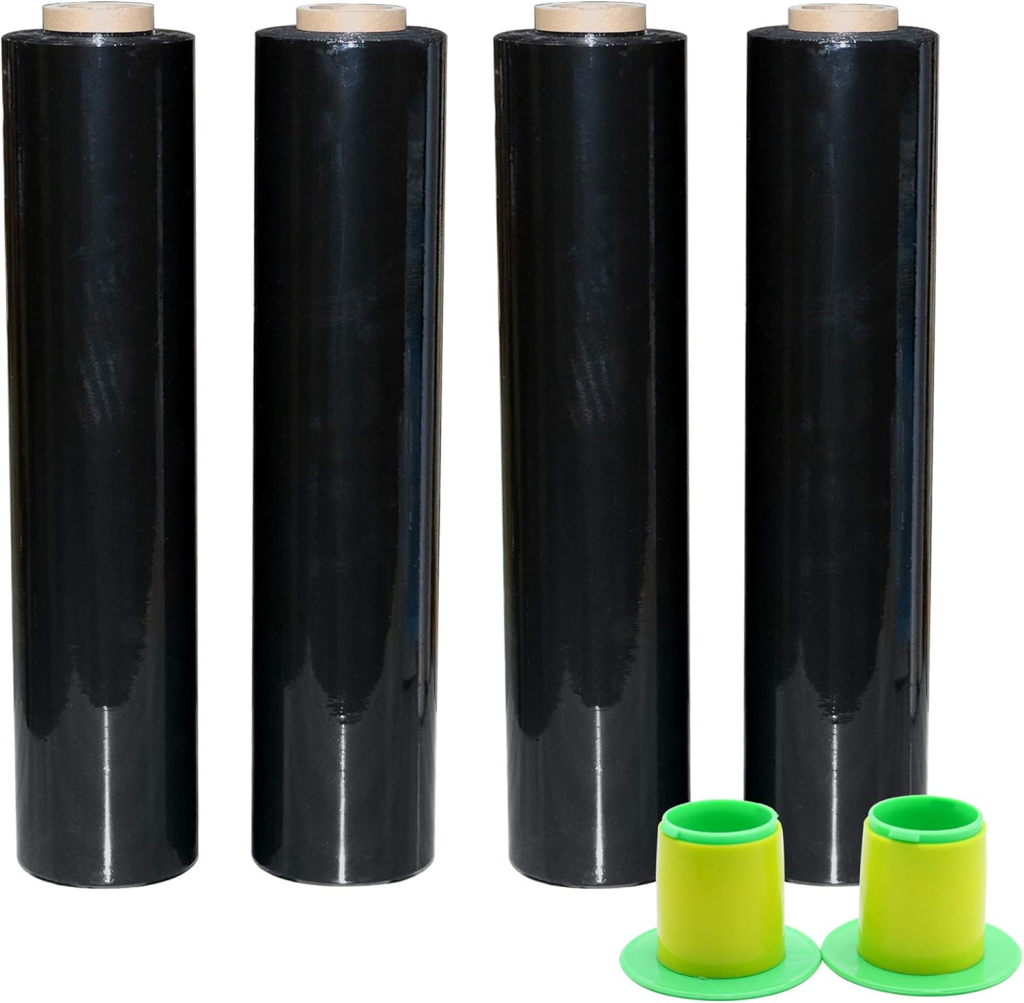

Black stretch film wrap is a type of plastic film designed to tightly secure products on pallets or bundles. Unlike transparent films, black stretch film wrap conceals the contents of the package, providing additional security and a professional appearance. Its elastic properties allow it to stretch and cling tightly, ensuring items remain stable during transport or storage.

The film is usually made from high-quality linear low-density polyethylene, which provides excellent durability and resistance to tearing. This makes it ideal for both industrial and commercial applications. Whether you are shipping finished products, raw materials, or sensitive items, black stretch film wrap can offer protection from dust, moisture, and physical damage.

Benefits of Using Black Stretch Film Wrap

Choosing black stretch film wrap comes with several advantages that make it a preferred choice in packaging and logistics:

- Enhanced Security: The black color prevents visibility of the contents, reducing the risk of theft or tampering during transport.

- Durability: It offers superior resistance to tearing and punctures compared to standard clear films, ensuring your products remain intact.

- Protection Against External Elements: Black stretch film wrap helps protect goods from dust, dirt, and UV exposure.

- Cost-Effective: It requires fewer layers to achieve the same level of protection as other films, saving both material and labor costs.

- Professional Appearance: Pallets wrapped in black film look neat and organized, which can enhance your brand image during shipments.

These benefits make black stretch film wrap an essential component for companies aiming to maintain product quality and safety during transit.

Key Factors to Consider When Choosing Black Stretch Film Wrap

Selecting the right black stretch film wrap involves evaluating multiple factors to ensure it meets your specific needs. Here are the key aspects to consider:

1. Film Thickness

The thickness of stretch film, often measured in microns or gauge, directly affects its strength and stretchability. Thicker films provide better load stability and puncture resistance, making them suitable for heavy or irregularly shaped items. On the other hand, thinner films are more flexible and economical, ideal for light loads.

2. Stretchability

Stretchability refers to how far the film can extend without breaking. High-stretch films can wrap more tightly around products, reducing the risk of shifting during transport. For unstable or top-heavy pallets, selecting a film with superior stretchability ensures maximum security.

3. Roll Size

Black stretch film wrap comes in various roll sizes and lengths. Consider the dimensions that best suit your packaging process. Larger rolls reduce the frequency of roll changes, improving operational efficiency, while smaller rolls offer better maneuverability and precision for hand wrapping.

4. Pre-Stretch vs. Hand Stretch

Pre-stretched film is designed to be used with stretch wrap machines, offering consistent tension and faster application. Hand stretch film, however, is ideal for manual wrapping in smaller facilities or for irregularly shaped items. Choosing the appropriate type depends on your workflow and packaging volume.

5. Adhesion Properties

A good black stretch film wrap should cling to itself without leaving residue on your products. Self-adhesive films improve load stability and reduce the number of layers required, saving time and material costs.

6. UV and Weather Resistance

If your shipments will be exposed to sunlight or outdoor conditions, UV-resistant black stretch film wrap is crucial. This type prevents degradation from prolonged sun exposure, maintaining its strength and appearance.

Common Applications of Black Stretch Film Wrap

Black stretch film wrap is used across a wide range of industries due to its versatility and protective qualities:

- Manufacturing: Securing finished products on pallets for warehouse storage or shipping.

- Food and Beverage: Protecting bulk items or packaged goods from dust and contamination.

- Retail: Concealing high-value merchandise during storage or transport.

- Construction: Bundling heavy materials or equipment for secure delivery.

- Logistics and Warehousing: Organizing and stabilizing pallets to prevent shifting during transportation.

Its ability to provide both protection and privacy makes black stretch film wrap a practical solution in almost every commercial sector.

Tips for Efficient Use of Black Stretch Film Wrap

Using black stretch film wrap effectively requires more than just wrapping your items. Here are some tips to maximize its benefits:

- Start from the Base: Always begin wrapping at the bottom of the pallet and work your way up to ensure stability.

- Overlap Layers: Overlapping each layer by 50 percent helps create a stronger, more secure wrap.

- Use the Right Tension: Applying too much tension can cause tearing, while too little can compromise load stability. Adjust the stretch according to the weight and shape of your items.

- Store Rolls Properly: Keep film rolls in a cool, dry area to prevent damage and preserve elasticity.

- Consider Automation: For high-volume operations, using a stretch wrap machine can save time, reduce labor, and ensure consistent wrapping quality.

These small adjustments can make a significant difference in protecting your goods and improving packaging efficiency.

Environmental Considerations

As sustainability becomes more important in business operations, considering the environmental impact of your packaging materials is essential. Many black stretch film wraps are now available in recyclable or partially recycled forms. Opting for eco-friendly options can reduce waste and support your company’s environmental initiatives without compromising on strength or performance.

Choosing the Right Supplier

Selecting a reliable supplier is just as important as choosing the right type of film. Look for suppliers who offer:

- High-quality, durable black stretch film wrap

- Consistent roll dimensions and thickness

- UV and weather-resistant options if required

- Flexible ordering and delivery options

- Competitive pricing with excellent customer support

A dependable supplier ensures you always have access to quality materials, minimizing downtime and potential losses.

Avoiding Common Mistakes

Even with the best black stretch film wrap, improper application can lead to problems. Common mistakes include:

- Using too few layers, resulting in unstable loads

- Choosing a film that is too thin for heavy items

- Applying inconsistent tension during manual wrapping

- Ignoring UV or weather resistance for outdoor storage

- Purchasing from unreliable suppliers, leading to quality inconsistencies

Avoiding these errors ensures that your products remain secure and your investment in black stretch film wrap pays off.

Enhancing Productivity with Black Stretch Film Wrap

Properly using black stretch film wrap can also improve overall workflow and productivity:

- Faster Loading and Shipping: Efficient wrapping secures pallets quickly, speeding up the loading process.

- Reduced Material Waste: Choosing the right thickness and stretchability prevents overuse of film.

- Fewer Damages: Secure packaging reduces product damage, returns, and replacement costs.

- Improved Inventory Organization: Wrapped pallets are easier to stack and identify, streamlining warehouse management.

By considering these operational benefits, businesses can make the most of their packaging materials.

Making the Final Choice

When deciding on a black stretch film wrap, balance cost, strength, and operational needs. Consider:

- The weight and shape of your products

- Whether you need hand or machine application

- UV exposure or environmental conditions

- Supplier reliability and consistency

Taking the time to analyze these factors ensures you select a film that meets both performance and budget requirements.

Maximizing the Impact of Your Packaging

Investing in the right black stretch film wrap is not just about protecting products. It is also about creating a professional image, enhancing security, and improving operational efficiency. By understanding the properties, applications, and proper techniques, you can ensure that every pallet and shipment reaches its destination safely.

Using black stretch film wrap wisely also demonstrates a commitment to quality and professionalism, making it a simple yet powerful tool for businesses across industries.